Product

AUQAMENT

Polymer-modified cementitious waterproofing membrane coating

Product

AUQAMENT

Polymer-modified cementitious waterproofing membrane coating

Description

Aquament is high flexibility polymer-modified cementitious waterproofing membrane coating made with an acrylic emulsion and a characteristic cement-based admixture.

Aquament overcomes the weakness of conventional similar products such as weather resistance and fatigue performance resistance, then it exhibits superior waterproofing performance over an extended period of time.

PRODUCT DETAILS

Em B emulsion:

- Color: White

- Appearance : Liquid

- Packing : 4.3kg bucket

A Powser

- Color: Gray

- Appearance : Powder

- Packing : 15kg bag

TECHNICAL REPORT

Pot life (20℃)

minute

30

Curing time (20℃)

hours

72

1.48

%

53

mm

1.3

0.4

Water Permeability

gr

Japanese Architectural Standard Specification JASS 8: Polymer-modified Cement Waterproofing Membrane Work Standard quality

PROPERTIES

Aquament is used for waterproofing of concrete structures with movement by the performance of high flexibility, regardless of whether underground or above ground in construction and civil engineering work.

- Suitable substrates: New, old or repaired concrete.

- Suitable areas

- Basement wall. (inside, outside) ・Water tank, Some pits

- Toilet, Bathroom, Kitchen ・Balcony, Small-scale roof

Features and benefits:

- Follow the crack by high flexibility.

- Excellent bond to damp or wet concrete.

- Easy to mix and apply.

- To use with exposure without deterioration due to UV rays.

- Environment friendly.

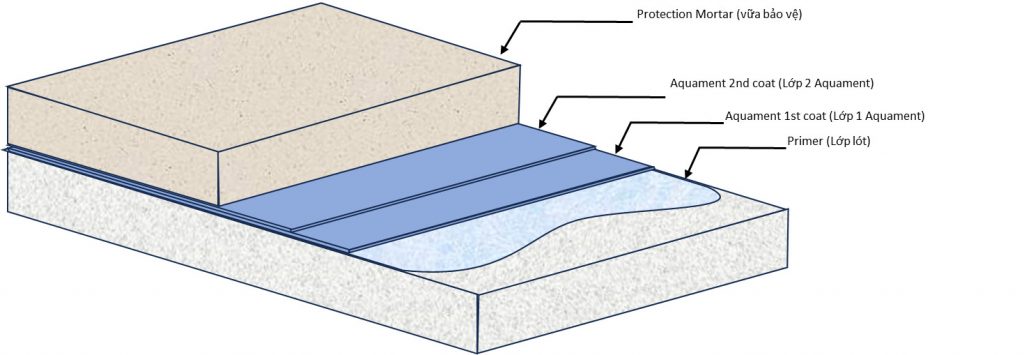

APPLICATION METHOD

1. PREPARATION OF SUBSTRATES

Application tool: Trowel, Wool roller, Brush

All substrates must be sound and free of all contamination including laitance, paints, coatings, oil, grease and dust. Concrete and cement render surfaces must be roughened by suitable mechanical means such as grit blasting, high pressure water jetting or needle gunning. Thoroughly dampen the whole area with clean water before applying Aquament.

2. MIXING

- Primer: Use only clean bucket and clean water. Add 3kg clean water to 1kg of Em B emulsion, then mix together well

- Waterproofing: Use only clean bucket. Add Em B emulsion into clean bucket, add A Powder gradually while mixing with ratio table

Em B

A-Powder

Wall or by trowel

4.3 kg

15 kg

Floor or by roller

4.3 kg

13 kg

Mix at least 3 minutes after adding all powder, to produce a smooth and homogeneous brush-able consistency until lump-free. After a ripening time of 1-3 minutes mix again shortly.

Batching Process (similar Aquashutter)

3. EXECUTION:

- Apply Primer with roller or brush.

- Then apply Aquament at least 2 layers by trowel, roller or brush after confirm the drying the primer. Respect a waiting time of 3-5 hours before applying second layer.

"Do not apply in direct sunlight or on a hot substrate

(depend on the condition)"

DOCUMENTS DOWNLOAD

Contact Us

We look forwards to collaborating with your company. Please fill in your information, we will contact at your earliest convenience.